Detail Information

| Property | Details | Property | Details |

|---|---|---|---|

| Place Of Origin | CHINA | Brand Name | Linkfuture |

| Certification | CE, SGS, ISO9001 | Model Number | LF |

| Product Name | Clear Paint Protection Film | Heat Resistance | Yes |

| Size | 1.52x15m/60inchx50ft | Scratch Resistance | High |

| Water Resistance | Yes | Healing Type | Self Healing |

| Color | Clear | Adhesive Type | Acrylic |

| MOQ | 1 Roll | Packaging Details | Accept OEM |

| Delivery Time | 5-7 Work Days | Payment Terms | L/C, D/A, D/P, T/T |

| Supply Ability | 100000 Roll/Month | Highlight | high gloss 7.5Mil ppf |

Product Description

Paint Protection Film (PPF) – Premium Defense for Luxury & Fleet Vehicles

Bulk Solutions for Wholesalers & OEMs – Scalable, Customizable, Industry-Leading Durability

Meet the demands of discerning automotive partners with Linkfuture, a high-performance gloss paint protection film (PPF) engineered for bulk applications. Designed for wholesalers and brands seeking OEM-grade quality, this film delivers unmatched clarity and 6+ years of UV/chemical resistance, ensuring vehicles retain factory-fresh brilliance across fleets, dealerships, or luxury aftermarket lines.

Wholesale Advantages:

Custom Sizing & Branding: Pre-cut kits for 100+ vehicle models, with optional white-label packaging.

Tiered Pricing: Volume discounts for 50 rolls orders, backed by UPS or FedEx logistics across Wordwide.

Certified Durability: Exceeds ASTM D7869 standards for abrasion resistance (-40°F to 200°F operational range).

Eco-Certified Adhesive: REACH-compliant, residue-free removal for sustainable reapplication.

Ideal for car wrap resellers and automotive brands, Linkfuture combines 7.5-mil thickness with nano-ceramic topcoat technology, reducing post-installation maintenance by 50% compared to standard PPF. Partner with us to elevate your catalog’s premium offering.

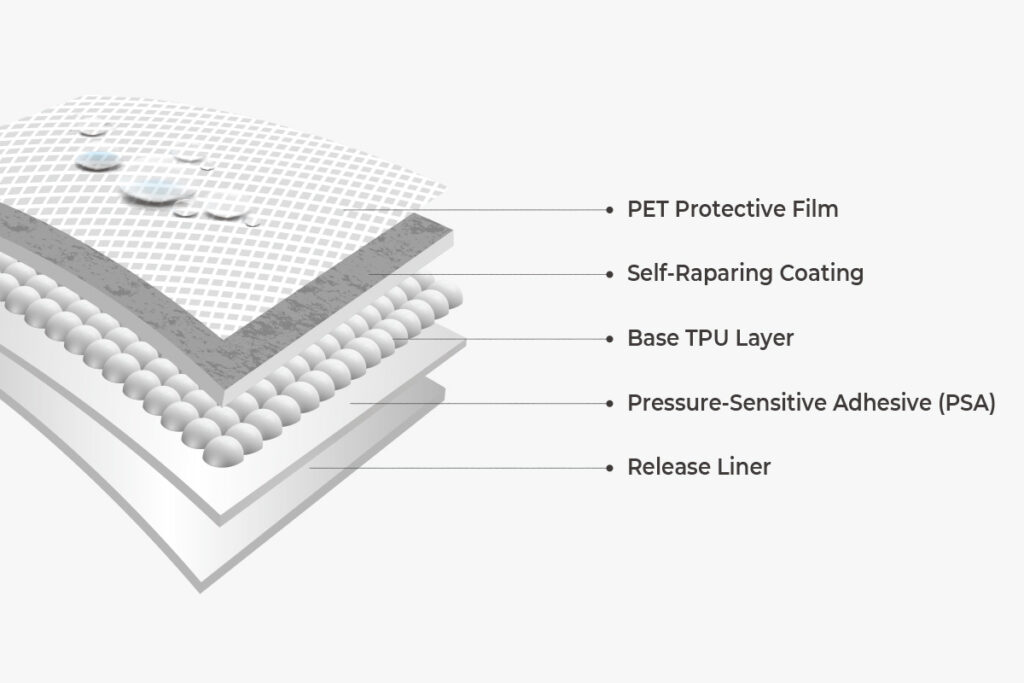

Product Structure

Prduct Specifications

| Classification | Unit | Spec | Remark | |

|---|---|---|---|---|

| Thickness | Clearcoat | µm | 50±2% | PET |

| Self-healing Coat | µm | 6.5±2% | / | |

| Face Film | µm | 160±2% | Thermoplastic Polyurethane | |

| Acrylic Adhesive | µm | 25±2% | Solvent based | |

| Release liner | µm | 75±2% | Satin Semi-transparent | |

| Surface | – | Matte Transparent | Super Glossy | |

| Width | mm | 1520±0.01% | 5ft | |

| Length | mm | 15000+1% | 49.21ft | |

| Adhesive appearance | – | Clear | ||

Product Performance

| Features | Test Method | Results |

|---|---|---|

| Release force N/25mm |

paste on steel board, 90° 26℃ and 60%, GB2792 | 0.27 |

| Initial tack N/25mm |

under 26℃ and 64%, GB31125-2014 | 9.5 |

| Peel Adhesion N/25mm |

paste on steel board, 180° 15 Minutes under 29℃ and 55%, GB/T2792-1998 | 9.35 |

| Holding power(h) | paste on steel board, hang on by 25mm*25mm*1kg weight under 29℃ and 55%, GB/T4851-1998 | >75 |

| Gloss(60°) | GB 8807 | ≥90(%) |

| Application temperature | / | +20℃ to +25℃ |

| Service Temperature | / | +20℃ to +80℃ |

| Humidity Resistance | 120 hours exposure | No Detrimental Effect |

| Salt spray Resistance | 120 hours exposure | No Detrimental Effect |

| Water Resistance | 120 hours exposure | No Detrimental Effect |

| Chemical Resistance | 1-hour diesel oil immersion, 4 hours antifreeze immersion | No Detrimental Effect |

| Aging Test 1 | 7 days under 70°C | No adhesive residue with heat |

| Aging Test 2 | 10 days under 90°C | No adhesive residue without heat |

| Elongation at Break | GB/T 1040 | ≥400 |

| Tensile Strength | GB/T 1040 | ≥20 (Mpa) |

| Elongation at Break of Self-healing Coat | GB/T 1040 | ≥85 |

| Application Method | Wet only | / |

| Time Limits | Must use it within 3 Months after you receive the wrap film | 3 Months |

Storage Period

2 Years from the Manufactured Date in Temperature Range of 68 F – 78 F (20 C – 26 C) Relative Humidity 50%, Indoor Storage

Common Applications

- Protection of the highly sensitive external surfaces of the vehicle like; bumper, side mirrors, hood, headlight & wheel arches.

- Protection of internal surfaces like, luggage racks or chairs in busses or trains

- Protection of surfaces in high traffic areas like, reception desks, door impact areas, wall panels and more

- Partial colour change to high gloss black to accentuate specific car parts like roof, mirrors, hood and more

Installation Guidelines

- Clean the vehicle thoroughly.

- Cut PPF sections with extra for trimming.

- Spray soapy water on the surface.

- Apply PPF, float on soapy water.

- Squeegee out air and water, starting from the center.

- Heat and stretch the film to conform.

- Trim excess film with precision.

- Repeat the process for each section.

Please remove the protective cap prior to installation.

Key Information to Note

- Screen Display: Please be aware that the screen’s images, colors, and finishes are approximate. For precise product representation, always refer to the color swatch.

- Consistency in Production: When undertaking a wrapping project, it is advisable to use rolls from the same production LOT number, as there may be slight batch-to-batch variations in color.

- Surface Vulnerability: The film may be susceptible to scratching during application or daily usage. It is important to note that the warranty does not cover any scratching of the film.

How Much Wrap Do I Need?

- Motorcycles: 3-5 meters (10-16 feet)

- Mini and Small Cars: 13-14 meters (42-45 feet)

- Convertibles: 15-16 meters (49-52 feet)

- Coupes: 17-18 meters (55-59 feet)

- Sedans: 17-18 meters (55-59 feet)

- Hatchbacks: 16-17 meters (52-55 feet)

- Sports Cars: 16-17 meters (52-55 feet)

- Station Wagons: 18-20 meters (59-65 feet)

- Sport-Utility Vehicles (SUVs): 17-19 meters (55-63 feet)

- Minivans: 20-24 meters (65-80 feet)

- Pickup Trucks: 22-28 meters (72-92 feet)

To ensure you have sufficient material for potential repairs, it’s advisable to add an extra 2-3 meters (6-9 feet) to your measurements. This precaution will help you avoid unexpected shipping expenses and delays.

To attain a flawless installation, here are some additional tips:

- Maintain a clean and dust-free workspace to prevent imperfections.

- Check for any surface imperfections or damage before starting the installation.

- Use appropriate cutting tools to trim excess material for precise edges and corners.

- Ensure the film is applied smoothly, without wrinkles or bubbles.

- During stretching, be mindful of the film’s limits to avoid overstretching.

- Pay special attention to corners and edges, making sure they are securely adhered.

- For complex curves or contours, use a heat gun or heat source to aid in molding the film.

- Periodically inspect and maintain the installed film to ensure long-lasting quality.

Following these additional guidelines will help you achieve the best possible finish and ensure the longevity of the installed PPF.

FAQ:

Q1: What MOQ applies to custom-branded gloss PPF orders?

A1: Minimum order starts at 50 rolls for custom branding. Bulk orders above 100 rolls. qualify for dedicated technical support and priority production scheduling.

Q2: Does your gloss PPF integrate with ADAS sensors?

A2: Yes – Our car protection film is tested for 100% radar/LiDAR transparency, ensuring compliance with advanced driver-assist systems in modern vehicles.

Q3: Can you provide installation training for our dealership network?

A3: Absolutely. We offer on-site/remote certification programs through our PPF Academy, covering cutting, heat-forming, and edge-sealing best practices.

Q4: How do you ensure batch consistency for large orders?

A4: Every roll undergoes spectral gloss metering (85-90 GU tolerance) and tensile strength testing. Certificates of Conformity accompany all shipments.